Designed for a range of slurry applications

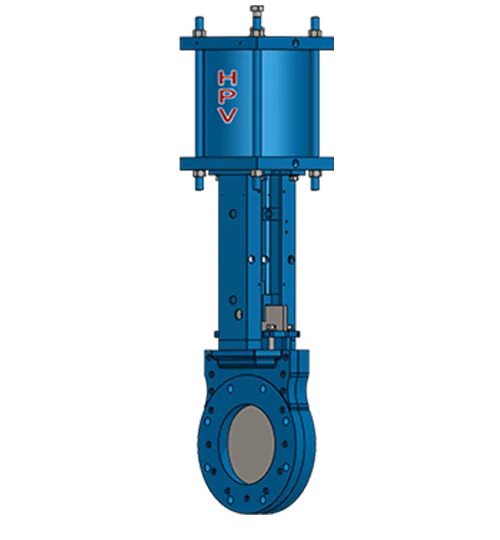

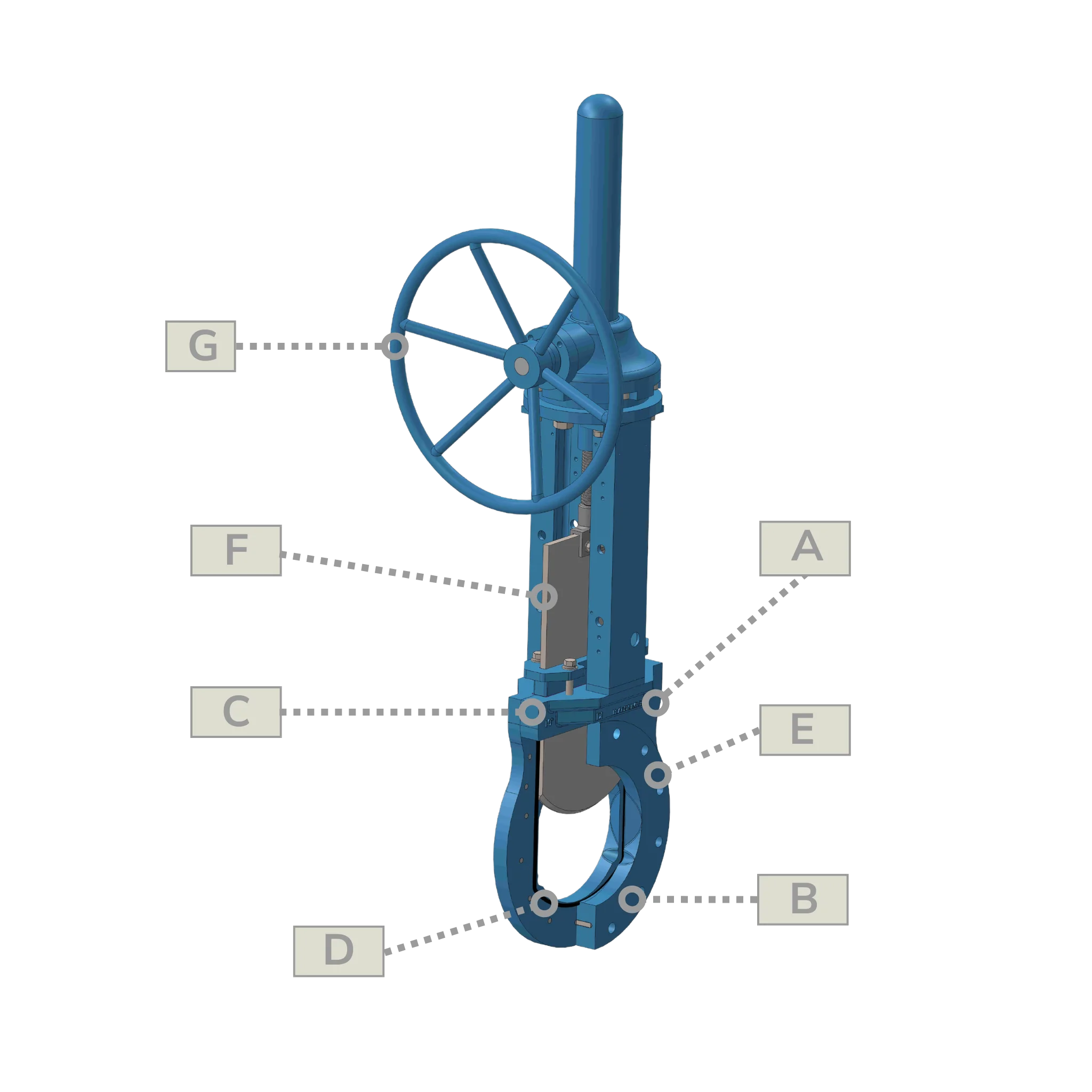

KS1 Series

Knife Gate Valve

Size Range 50mm / 2″ – 600mm / 24″

Body Style Two Piece Body

Body Epoxy Coated SG Iron

Pressure Rating 300 psi / 2068kPa

Gate 2205 Duplex