Designed for high temp. acidic solutions

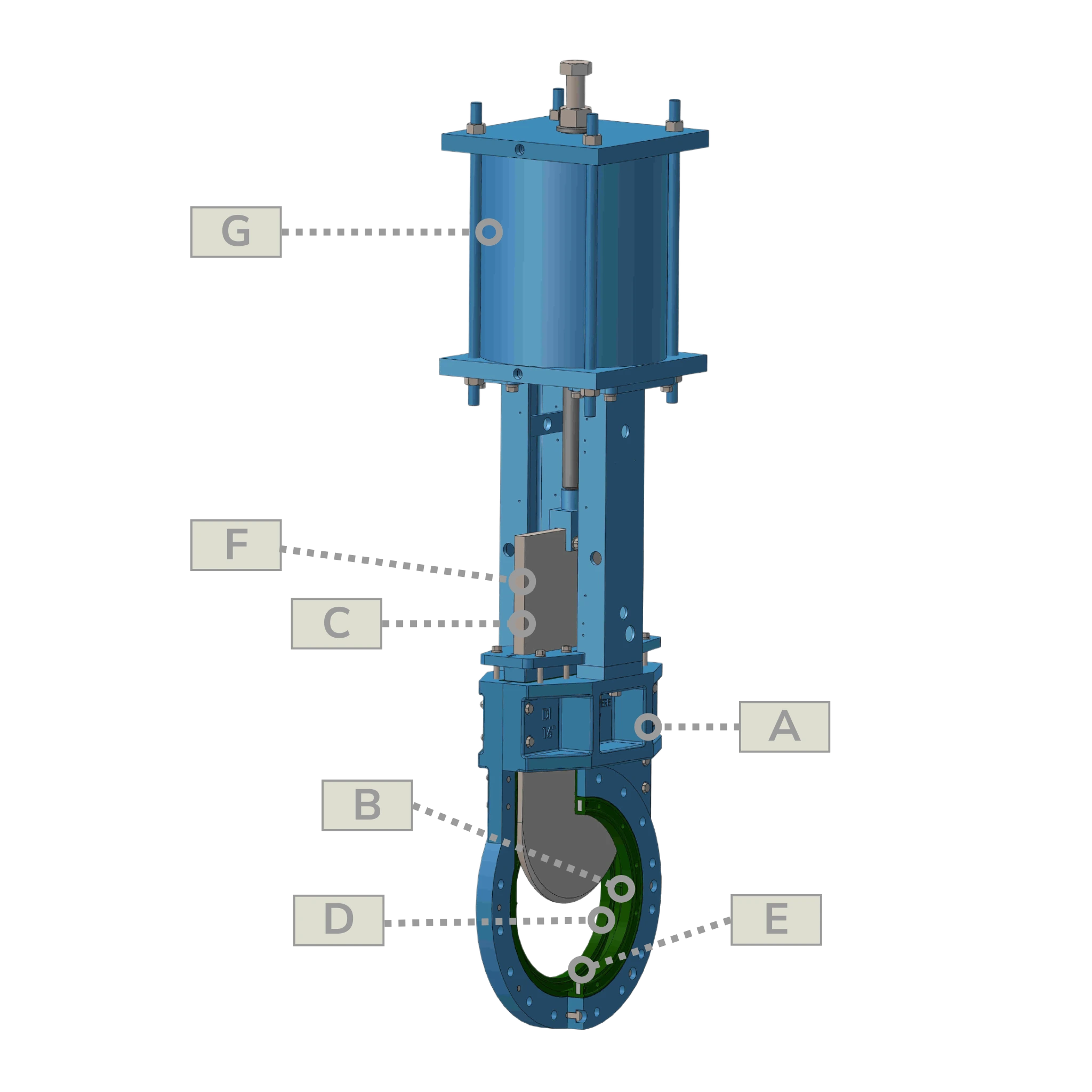

KGI-XT Series

Knife Gate Valve

Size Range 50mm / 2″ – 900mm / 36″

Body Style Two Piece Body

Body Epoxy Coated SG Iron

Pressure Rating 102 to 232 psi

Gate 2507 Duplex