Learn more about our Knife Gate Valves, Butterfly Valves & Ball Valves

We ‘re leading providers of slurry valves for the mineral and processing industry. Serving various industries such as mining, oil and gas and pulp and paper. As well as power generation, water, and related industries. Our clients include design, lead pipe, and project engineers of all major EPCM’s that design mineral processing plants.

We have supplied slurry valves and complete valve packages for many projects globally. Our main product range includes knife gate, butterfly and ball valves. All available with different gate options, drilling types and patterns.

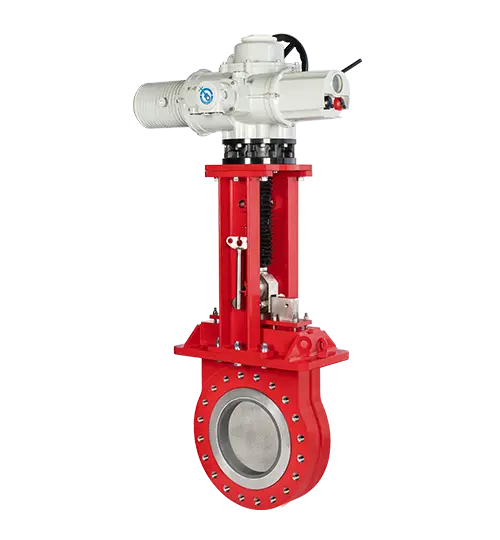

Manual, Electrical or Pneumatic Actuation

We also offer various actuation options and gear box options to best suit your workflow. For actuation devices such as Hand Wheels or Pneumatic Actuators – we’ve got you covered.

Our experience with different applications enables us to recommend appropriate solutions. We’re committed to ensuring our products and services are of the highest standard. Speak to our expert team today, who can assist with your specific requirements.

What is a Knife Gate Valve?

A knife gate valve isolates the flow of pipeline media by lowering the gate (knife) into the seat. The lowering of the gate will then shut off the pipeline. Raising the gate will open the valve and allow flow through the pipeline. The gate moves via a manual hand-wheel, gearbox, or a choice of pneumatic, hydraulic, or electrical actuators. These types of valves are isolation valves and are not made to control flow. They are either fully-opened or fully-closed. Please note we have a range of slurry control valves we can provide if you need control.

A knife valve is effective in mineral processing plants with pipeline media. Media such as slurries and solutions are difficult for a lot of gates to operate in. The knife’s sharp blades enable an easy cut through heavy liquids. This makes the gate valve knife a recommended gate for harsh environments.

Hy-Performance Knife Gate Valves - Reliable, Zero-Leakage & No Unwanted Discharge

Our Knife Gates at Hy-Performance focus on providing high quality, reliable mining valves. This reliability enables our customers to have peace of mind on-site. Our wide range includes valves with integrated seats, which guarantee zero leakage. Zero leakage means zero risk of pipeline media leaking onto surrounding equipment. Besides zero leakage, our gate valve knifes also ensure no discharge during operation.

Featured in this range, is our exclusive KGI Series Knife Gate Valve. The KGI is an industry renowned valve for difficult slurry applications. The patented design provides a rugged body, replaceable liner, and an extra-thick stainless steel gate. The long-lasting, durable qualities of the KGI Series have made this a popular pick. The slide gate valve is a perfect on/off knife valve.

For high pressure applications, we have a Class 150 valve, as well as Class 300 valve body. Both of these bodies are available in our KH Series Knife Gate Valve. The pressure chamber with energised packing, eliminates leakage from the gland. Making the KH ideal for high density slurry & tailings.

We also provide metal seated valves for general slurry applications – such as the HSM Series. As well as the HSR Series for dirty water and suspended solids.

Knife Gate Valve Dimensions

We provide various size options in our Knife Gate Valve range. Most of our range varies from 50 to 900mm (2 inch to 36 inch knives). For face to face dimensions, weight information and more – contact our team today.

The standard construction of our knife gates includes Epoxy Coated Ductile Iron and Carbon Steel bodies. With a choice of gate materials such as 316 SS, 304 SS, 2205 Duplex, 2507 Duplex, Hastelloy C22, Hastelloy C726, Titanium Grade 12 options.

Butterfly Valves

Butterfly valves feature a rotating disc which opens/closes to regulate flow. Part of the quarter-turn family of valves, the butterfly is quicker to shut off than other choices. Their speedy on/off functionality enhances process efficiency. Butterfly valves perform best in lower pressure applications. But, there are design options to make the valve withstand higher pressure. We provide options to operate these manually or automatically via an actuator.

In our range we have the S Series Butterfly Valve, ideal for chemical and acidic solutions. With a PFS encapsulated disc with TFM Liner, the S Series offers a perfect sealing system.

Ball Valves

Like the butterfly valve, the ball is also part of the quarter-turn valve family. Its design enables flow control through a spherical ball with a hole in its center. The ball offers a tight seal, ensuring little to no leakage even in harsh conditions. The tight seal makes the ball valve ideal for on/off control. Featured in this range is the A-Series Ball Valve, made to handle aggressive media. For information on different ball types we offer – please enquire today.

For more information on any of our valves, please get in touch with one of our experts today. With 80+ years of combined experience, we deliver high performance solutions for the industry. We’ll be able to assist you with the right valve solution for you.